© 2025 WADI e.V.

Webdesign by Nyx Alexander Design

In

the

past,

gypsum

was

one

of

the

most

important

building

materials

in

the

region

around

Koya.

However,

due

to

the

use

of

cheaper

cement,

it

has

almost

fallen

into

oblivion

as

a

mortar,

a

problem

that

current

restoration

projects

in

the

Old

Town

of

Koya

are

struggling

with.

Nowadays,

gypsum

is

only

used

as

gypsum

plaster,

which

requires a different, simpler production method.

The

General

Director

of

Antiquities

and

Heritage,

Kaify

Mustafa

Ali,

the

Department

of

Antiquities

in

Koya

(Yekaty

Wahip

and

Hemin

Kawez),

WADI

e.V.

(Anne

Mollenhauer)

and

Klessing-Hoffschildt

Architects

(Andreas

Hoffschildt),

have

therefore

begun

to

revitalize

this

old

craft

tradition

with

the

generous

support

of

the

German Gerda Henkel Foundation.

In

March

2024

a

survey

of

the

quarries

in

the

region

was

conducted,

in

cooperation

with

the

University

of

Koya

(Manar

Ahmad),

the

University

of

Dohuk

(Shireen

Younis)

and

geologist

Michael

Krempler,

to

select

good

quality

quarries

near

Koya

City

that

also

have adjacent, unused plaster kilns.

A

firing

site

near

Koya,

which

also

has

a

rich

quarry,

was

selected.

Three

combustion

chambers

were

repaired

together

with

an

experienced old gypsum burner, and a new gypsum burning process was started on an experimental basis.

The

aim

was

to

burn

plaster

at

high

temperatures

and

to

achieve

a

broad

distribution

of

fine

and

coarse

particles

in

the

grinding

process.

The

analysis

of

historical

plaster

mortars

from

the

Mahmud

Agha

Khan

in

Koya

(1860

A.D.)

gave

us

the

parameters

that

now

had

to

be

achieved

experimentally;

local

experience

of

firing

plaster

at

high

temperatures

has

been

dormant

for

many

years

- Kak Salim, for example, has not worked in this field for over 20 years.

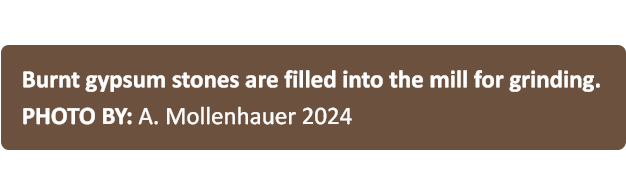

The

challenge

began

with

the

purchase

of

the

necessary

equipment:

an

old

truck

whose

drive

shaft

operating

the

stone

mill,

the

restoration

of

an

old

stone

mill

that

had

been

unused

for

many

years,

the

correct

adjustment

of

the

burner:

a

mixture

of

diesel

and waste oil, the flame of which is regulated with the help of compressed air.

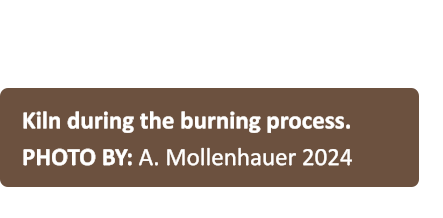

The

firing

process

itself

takes

one

day

(approx.

9-10

hours)

the

stones

piled

up

to

form

a

false

vault

were

fired,

followed

by

a

day

for

cooling,

and

on

the

third

day

the

stones

were ground and packed in bags.

For

long-term

observation,

we

rebuilt

a

destroyed

rear

wall

of

the

khan,

which

now

serves as an open-air test area.

Four

weeks

later,

the

plaster

was

already

being

put

to

practical

use:

The

Department

of

Antiquities

in

Koya

began

restoring

the

Malai

Gawra

house

in

the

old

town

and

immediately

used

the

new

gypsum

mortar,

much

to

the

delight

of

the

masons

involved,

who praised its quality highly.

The

analyses

and

tests

carried

out

in

Germany

and

Koya

confirmed

the

quality

of

our

new

mortar,

even

if

it

did

not

initially

reach

the

values

of

the

historical

mortar

samples

taken

from

the

Khan,

but

long-term

monitoring

showed

that

after

six

months

we

almost achieved the values of the historic gypsum mortar.